1. PEM FC water management

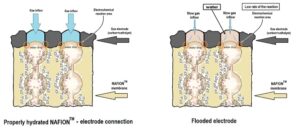

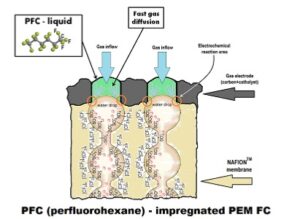

Current polymer electrolytes (NAFIONTM) membrane comprises of hydrophobic reticulated structure and percolated hydrophilic channels

These channels are the clue for the membrane proton conductivity – only hydrated membrane (i.e. the membrane with water-filled hydrophilic channels) conducts protons.

The problem:

From one hand, there should be enough water to fill the channels for providing adequate conductivity; i.e. the membrane should be hydrated.

From another hand, excessive water floods the electrodes and thus hinders gas delivery toward reaction zone.

The solution:

To impregnate a fuel cell electrode with liquid perfluorinated carbons (PFC). These liquids are hydrophobic and also have an extremely high oxygen and hydrogen solubility and diffusivity.

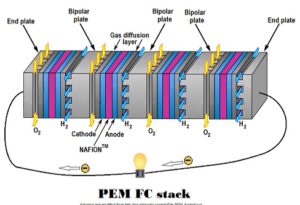

2. PEM FC bipolar plates contact conductivity

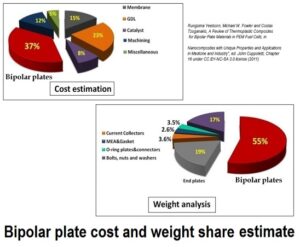

Bipolar plates, which connect the individual cells, seem to be the simplest part of the stack; they looks like to be prepared from non-precious materials (as electrodes with catalyst) and seemingly don’t have witty molecular -scale structure (as gas diffusion layer, catalyzed electrodes and polymer electrolyte membrane).

It turns out again that “truth is in the details”, though. As the matter of fact, bipolar plates make up the large proportion of the total weight and cost of the FC stack.

The reason is that high stack currents suggest very strict requirements for all resistances of the in-structure stack conductors. A critical area is bipolar plate – electrode contacts.

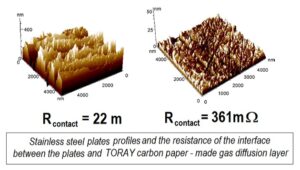

This makes the research in the field of the contact resistance really important.

Our investigation reveals that the contact resistance between gas diffusion layer and bipolar plate substantially depends on the bipolar plate surface morphology and particularly its profile.

We have demonstrated that a bipolar plate with a finely polished surface may have higher contact resistance then a bipolar plate with a considerably rough surface.

It may be suggested that for each material an optimal surface profile roughness exists, which provides the lowest contact resistance.

Bipolar plates, which connect the individual cells, seem to be the simplest part of the stack; they looks like to be prepared from non-precious materials (as electrodes with catalyst) and seemingly don’t have witty molecular -scale structure (as gas diffusion layer, catalyzed electrodes and polymer electrolyte membrane).

It turns out again that “truth is in the details”, though. As the matter of fact, bipolar plates make up the large proportion of the total weight and cost of the FC stack.